- Products

Tungsten Alloy

Tungsten

- Custom Designs

- About Us

- Knowledge

- Contact Us

T&D Advanced Radiation Shielding

Tungsten Alloy Radiation Shielding Lead Free

Tungsten Alloy Radiation Shielding Lead Free

Tungsten has a density that is roughly 1.7 times greater than lead, making it an optimal choice for shielding applications. Tungsten is a viable option for applications where lead is not feasible, for example, size reduction and maximizing weight in large and small cavities for radiation shielding. Tungsten is a strong material that can be highly customized into precision components.

In medical and industrial realms where radiation protection is paramount, tungsten is often the preferred option. It achieves the same absorption levels as lead while utilizing less material, aligning with ALARA (As Low As Reasonably Achievable) principles. Its machinability, density, strength, and non-toxic nature facilitate versatile design possibilities are unmatched by other shielding materials.

Lead, finds extensive use in diagnostic imaging, radiation therapy, and industrial contexts. Its high density and atomic number, along with high linear and mass attenuation coefficients, render it effective against X-rays and gamma radiation. However, lead poses health risks if ingested or inhaled, necessitating cautious handling.

Gamma rays present significant health risks by damaging surrounding cells. Shielding materials interact with gamma radiation, attenuating its intensity based on factors such as atomic number, density, and thickness. Effective radiation shielding is imperative to safeguard human health and the environment.

The choice of shielding material hinges on factors like cost, weight, durability, and toxicity. Materials with high density and high atomic numbers typically offer superior attenuation capabilities.

The adverse health and environmental impacts of lead create a need for alternative shielding materials. Tungsten emerges as a great option due to its non-toxic nature, high density, and superior shielding properties, serving as a promising substitute for lead in various applications.

The Benefits of Tungsten Shielding are:

- High radiation attenuation

- Easy to keep clean & sterilize

- Non-Toxic material

- Dimensionally stable up to 1000°c

- Hard & Durable (no need for steel or plastic coating)

T&D tungsten alloys find versatile applications across various industries. They are utilized in radioactive source containers, gamma radiography, shields, and source holders for oil-well, logging, and industrial instrumentation. High-density alloys serve crucial roles as collimators and radiation shielding in cancer therapy, in addition to syringe protection for radioactive injections.

When precise control over radiation direction is essential, tungsten alloys offer the necessary control. Our high-density alloys consistently deliver optimal performance, even under high-heat conditions.

In comparison to conventional radiation shielding materials, tungsten alloys offer exceptional value. A high-density alloy can match the energy absorption of lead while requiring only one-third of the material! Moreover, by using tungsten alloys, you can streamline administrative processes and reduce costs as special licensing is unnecessary, unlike with lead.

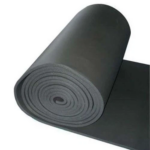

Besides sintered finished tungsten alloy and pure tungsten products, we also provide tungsten polymer for your dose reduction needs. Product offerings include:

- Blankets

- Safety Floor Shields

- Pipe Wrap

- Pipe Shields

- Magnetic Shields

- Custom Designed Shielding

NON-LEAD NUCLEAR SHIELDING BLANKETS

- Bulk shields used to shield larger areas of radiation, produced in standard sizes: 1’ x 2’, 1’ x 3’, 1’ x 4’, 1’ x 5’, 1’ x 6’, and 2’ x 3’

- PVC laminate covering (optional)

- Density can be as high as 11.4 g/cc

NON-LEAD NUCLEAR PIPE SHIELDS

- Pipe Shields are sized and formed to shield radiation from piping while meeting standard weight limitations

- Designed to slip on, encase, and snap tightly around the pipe

- Available in both standard and custom sizes

- Designed for optimal thickness at Co-60, and to prevent streaming

- Density can be as high as 10.50g/cc

NON-LEAD RADIATION FLOOR SHIELDING

- Floor shields improve radiological and industrial safety in work areas with moderate to high traffic

- Made with maximum shielding to provide maximum attenuation

- Traction tread can be incorporated to maximize worker footing

NEUTRON SHIELDING

Neutron Shielding involves a polyethylene container with dispersed low atomic element materials to effectively moderate and thermalize incident neutrons. Surrounding the container is Bismuth shielding to reduce gamma radiation doses resulting from neutron capture interactions. This combination efficiently attenuates various levels of Alpha particles and their high-intensity by-products.

Our Tungsten metals possess the necessary properties for radiation shielding in both therapeutic and diagnostic settings. They find widespread use in applications such as collimators, syringe and vial shields, and radioactive source containers.

T&D is actively involved in Nuclear Medicine applications, where our tungsten base materials play a vital role in radiation shielding for drug storage and delivery, containment vessels, shielding and directional focus apparatus. Notably, they offer effective protection without the health or environmental risks associated with lead.

The nominal tungsten content ranges from 90% to 97% and densities between 17 and 19 g/cm3.

Tungsten Radiation Shielding Parts Applications:

| Nuclear Shielding Wall | Tungsten Alloy FDG Container | Tungsten Heavy Alloy Inspect Welds | Nuclear Testing Equipment |

| Radiation Shielding Barrel | Isotope Production, Transport, and Containment | Large Container Inspection Devices | Oncology Isotopic and Accelerator Based Platforms |

| Pipe-Line Inspection Gamma | Defense for Nuclear Submarines | Shielding Components for X-Ray Tubes | Syringe Protection for Radioactive Injections |

| Isotope Containers for Brachytherapy | Shutter Blades for Computer Tomography | Shielding Elements for Detectors | Shielding Elements for Linear Accelerators |

| Radioactive Source Containers | Gamma-Ray Protection | Radioactive Source Holders for Oil Well, Logging, and Industrial Instrumentation | Collimators and Shielding for Cancer Therapy Machines |

| Gamma Radiography Tungsten Alloy Radiation Shielding | Tungsten Alloy Radiation Shielding Block | Tungsten Alloy Radiation Shielding Source Holders for Oil Well Logging | Tungsten Heavy Alloy X-Ray Collimators |

| Tungsten Alloy PET Syringe Shield | Shielding in Cancer Therapy Machines | Tungsten Heavy Alloy Syringe Shielding |